A few solid steel rivets have been observed.īrass rivets were often darkened with paint, and steel rivets were Parkerized. Both were semi-tubular and were rolled over the plate on the inside. Rivets used during this time period were brass and later steel. Of production, although Overton had to spend time and money to insure that the items manufactured by Royal Typewriter met Ordnance standards. Royal Typewriter's inventory was sufficient to sustain the needs of Overton until the end M1A1 stock and relocated it to the Overton facility in Michigan. Overton purchased all of Royal Typewriter's equipment and inventory related to the Poor quality control at Royal Typewriter prompted Overton to cancel their contract by May 1944. Richardson Companies of Sheboygan Falls, WI, to manufacture the hand grip. Initially Overton also made the hand grips but due to their workload and the complexity of manufacturing the hand grip, Overton Again, Overton manufactured the forestock. Overton and Royal Typewriter were used and intermingled with stocks and parts manufactured during the second production run until the inventory The M1A1 stocks and parts left over from the first run at S.E. Included a two-rivet handguard, narrow barrel band, flip rear sight, and push-button safety. Consistent features of the carbines in this range

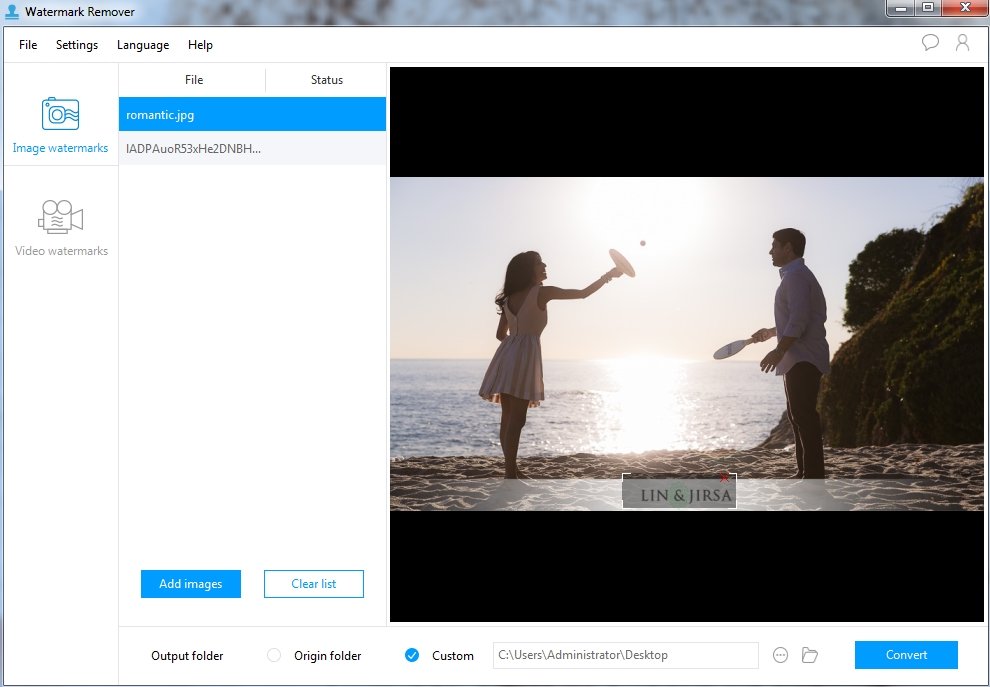

PHOTO STAMP REMOVER 7.4 SERIAL SERIAL NUMBERS

Serial numbers of the Inland M1 carbine actions made during this period ranged from 70,000 - 950,000, and many of these actions were put into M1A1 stocks.

Ordnance cannons stamped on bottom of grip (discontinued during the latter part of 1st run) Walnut Highwood OI stamped inside stock at rear of slide opening

These would not have had the Ordnance crossed As with other carbine parts, a percentage of M1A1 stocks and parts were produced as replacements. Ordnance acceptance marks in the form of the Ordnance crossed cannons were not added until after the stock was added to the carbineĪnd the completed carbine passed a final Ordnance inspection. Overton inspected the finished stocks and forwarded them on to Inland. The face of the rivet was often darkened with paint. Rivets used on the first run were semi-tubular brass. Was subcontracted to manufacture all of the hardware, receive the wood components from Overton, then assemble and return the completed stocks to Overton. For the first run, Overton manufactured the forestock and grip. Overton of South Haven, MI, for the manufacture of all of their M1A1 stocks. The months and quantities presented on this page are best estimates based on reviews and evaluations of all available documents, interviews and experiences. Army Ordnance have conflicted with one another in regards to monthly M1A1 production and deliveriesĭuring WWII. * Documents from Overton, Inland and U.S. The first three producing M1A1 stocks that were predictably consistent. The manufacture of M1A1 stocks can be divided into three basic time periods with The individual stock parts are described inįurther detail in the Parts Section below. This section will focus on the chronology of M1A1 stock production with a general description of the carbines placed within the stock variations. Varied significantly over time and are still a subject open to some degree of debate, the M1A1 stocks were made in far fewer numbers with far fewer variations during a shorter period of time. Whereas the features of the carbines that went into the stocks Serial numbers were whatever Inland serial numbers reached the assembly point at the time the stock was added. Government Printing Office, 1953ĭuring the ongoing production of the Model M1 Carbines, M1A1 carbines were made by placing a complete M1 action into an M1A1 folding stock instead of the regular M1 stock. *number of parts varied as minor changes were implemented and do not include aĬomplete breakdown of the rear sight and barrel band Made during WWII were carbine actions manufactured by Inland and placed into M1A1 stocks manufactured by Inland's subcontractors. No markings identifying the Model M1 from the Model M1A1 were added or changed anywhere on the carbine or its parts. Remained the same as those of the Model M1.

PHOTO STAMP REMOVER 7.4 SERIAL FULL

The Inland design was simply a side-folding stock any carbine action could be placed into, in lieu of the full length stock of the Model M1 Carbine. A patent application for the design was submitted and granted Revised Inland drawings were recommended for standardization as the Model M1A1 Submissions by two other sources were found to be unacceptable. The Inland Division of General Motors submitted their first drawingsįor such a design during March 1942. Issued a request for submissions of designs for a shorter version utilizing a folding or collapsible stock. 30 Carbine, Model M1, the need for a shorter version for use by paratroopers became evident. Right click on the image to view the model

0 kommentar(er)

0 kommentar(er)